Shanbo Drives Excellence in Automotive Air Duct Systems – A Symphony of Precision

“Shanbo not only met but exceeded our expectations with flawlessly finished parts.”

Sailing with Speed – Automotive Innovations by AT Solutions

Step into the world of AT Solutions, where automotive innovation takes flight. AT envisions a future where every drive is a harmonious blend of performance and efficiency. Their commitment to pushing the boundaries of automotive technology aligns seamlessly with Shanbo’s ethos.

Project Overview: Crafting Precision for Automotive Air Duct Systems

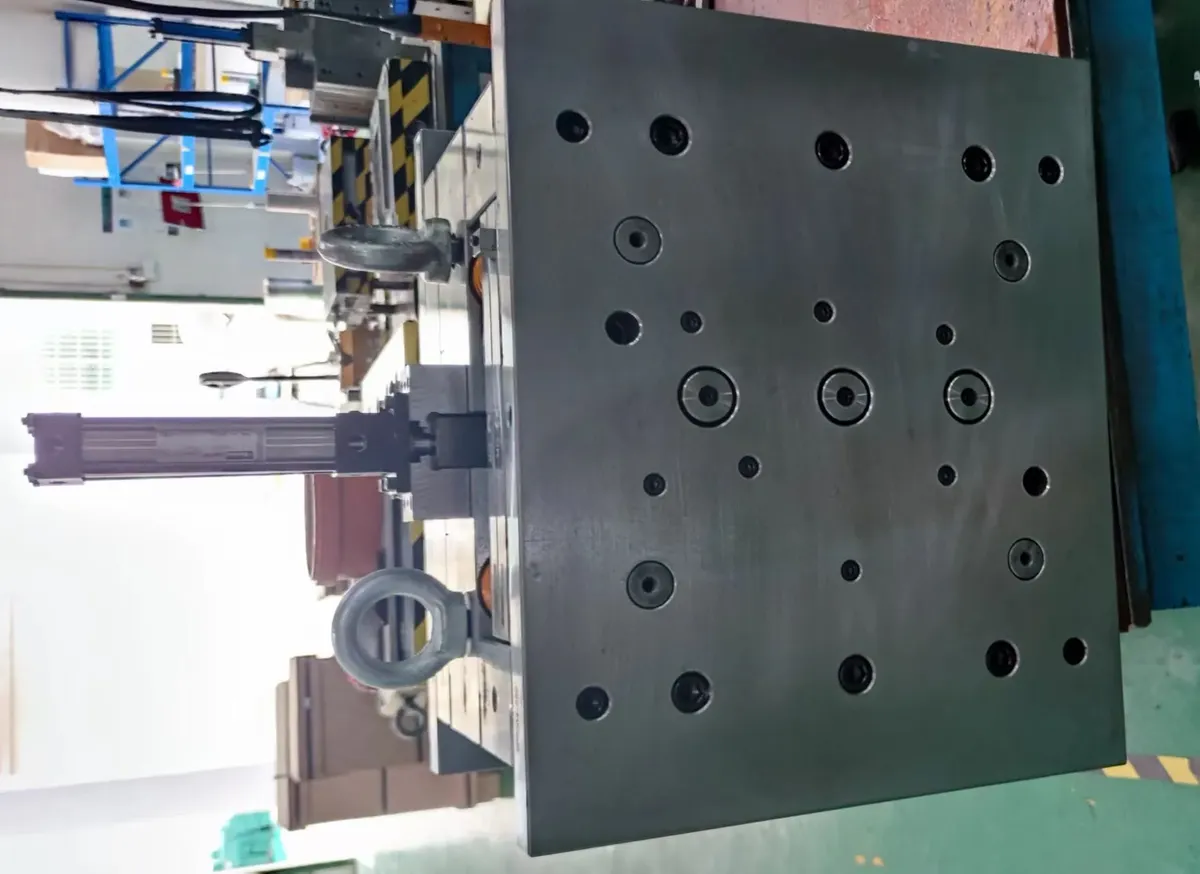

In a swift 3-week timeline, the challenge was set — deliver rapid molds and 50 parts for testing in the realm of automotive air duct systems. Despite being internal components, the unique requirement was to minimize noise generated by airflow, demanding flawless finishes with no burrs or internal surface defects.

- Mold Material: P20

- Part Material: PP

- Surface Finish: Directly Extracted from the Mold

- Delivery Time: 21 Days

Challenges: Minimizing Noise in Internal Components

The specific focus on manufacturing processes and quality control in this injection molding project emphasized the attention to detail. Not all internal components require perfection, as many are unseen. However, even the unseen parts need flawless functionality to achieve the desired performance.

Though internal, the components required meticulous attention to minimize noise generated by airflow. The final results demanded a flawless finish with no burrs or internal surface defects.

Result

The flawless tooling and an additional focus on quality control during the injection molding process ensured the desired final results.The rapid mold was completed on schedule, and the 50 parts were delivered within the 3-week timeframe, showcasing Shanbo’s commitment to meeting tight deadlines.

Highlights:

- Unique Challenges, Unique Solutions: Tailoring solutions to unique challenges, such as minimizing noise in internal components, showcases our ability to provide customized and effective solutions.

- Swift Prototyping Excellence: In the realm of rapid prototyping, excellence in quality is not negotiable. Shanbo’s commitment to one-shot excellence ensures timely delivery without compromising on quality.

- Attention to the Unseen: Even components that remain unseen demand flawless functionality. Attention to detail in manufacturing processes and quality control ensures unseen parts contribute seamlessly to the overall performance.

“Shanbo not only met but exceeded our expectations with flawlessly finished parts. The attention to detail in tooling and the additional focus on quality control during the injection molding process showcased their dedication to perfection, enabling swift testing without compromising on quality.” Said James Thompson, Senior Engineer of AT Solutions

At Shanbo, we don’t just mold parts, we craft precision solutions. Connect with us for your rapid prototyping and injection molding needs.