Casting porosity is the hidden enemy in manufacturing. You design a structurally perfect component, but voids inside the solidified metal undermine its integrity. For manufacturers dealing with aluminum die casting—especially for high-precision automotive or industrial parts—this is the most persistent barrier to reliability.

Industry standards often demand "zero defects," but physics makes that hard. Eliminating every single microscopic void is often technically impossible or cost-prohibitive.

So, how do we handle it?

Precision die casting isn’t about crossing your fingers. It’s about three things: control, quantification, and intelligent design. You need to understand the die casting defects you are fighting and engineer a process that mitigates them.

Know Your Enemy: Gas vs. Shrinkage

To fix a problem, you have to identify it correctly. Not all holes are the same. Casting porosity comes from two distinct physical mechanisms: trapped gas or shrinking metal.

Here is how to tell them apart:

Distinguishing between these is critical. If you see round holes, look at your melt quality or venting. If you see jagged holes, your die casting tooling likely has a feeding or thermal balance issue.

Why HPDC is Tricky

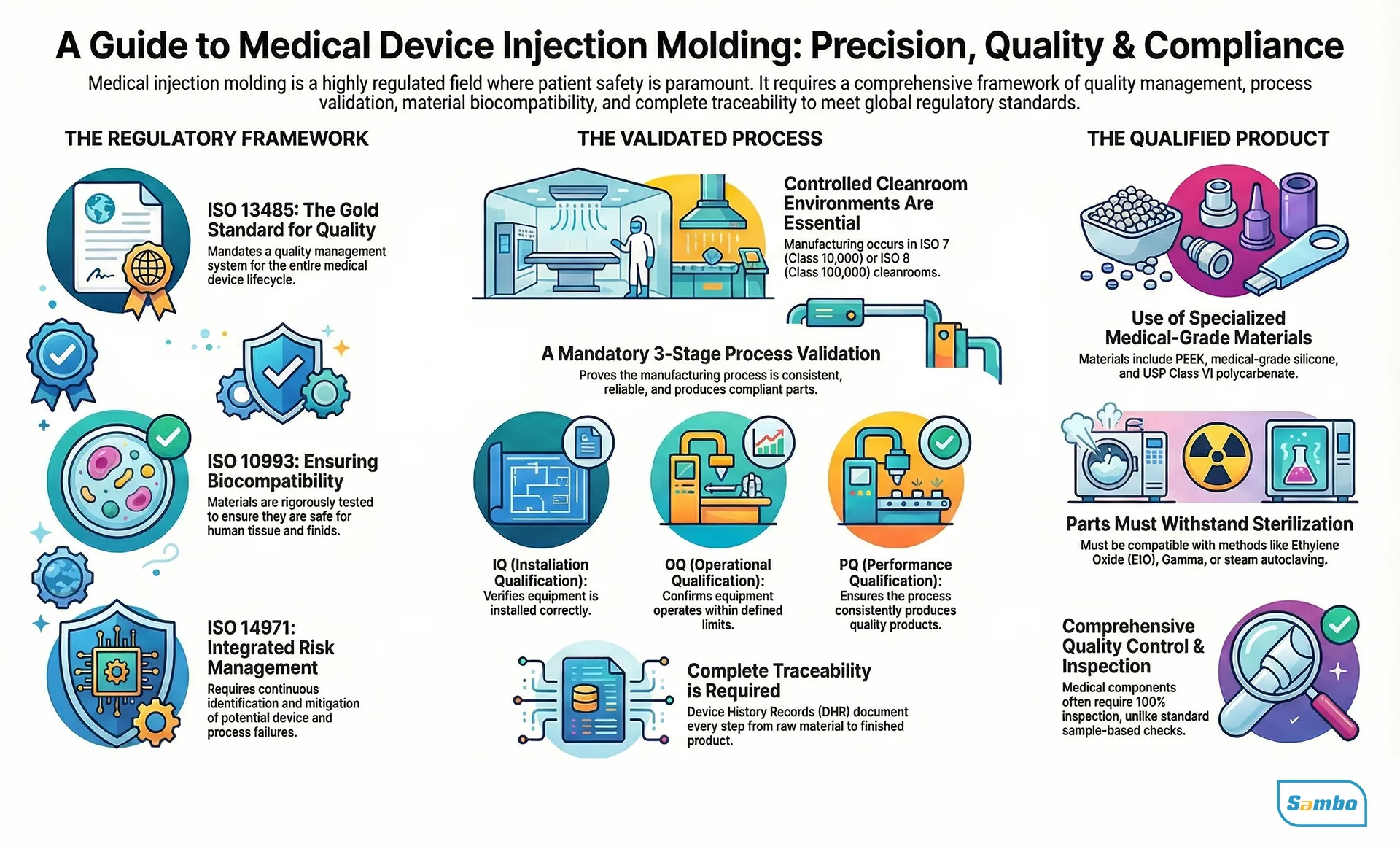

High-Pressure Die Casting (HPDC) is valued for speed and complex geometries, but the process itself is violent.

Molten metal gets injected at extremely high velocities. Research shows that mold filling in HPDC is highly turbulent—more akin to spraying a hose than a smooth laminar flow. This turbulence traps air easily.

Furthermore, feeding the casting during the critical solidification phase is limited. You typically rely only on the intensification pressure supplied via the plunger after the gate solidifies. This combination makes HPDC inherently prone to both gas entrapment and shrinkage voids.

It’s Not Just Cosmetic: The Impact on Fatigue

Porosity acts as a stress concentrator. It creates a weak point where cracks can start.

This is the single biggest factor influencing the fatigue life of aluminum die casting components. It lowers yield strength, ultimate tensile strength (UTS), and ductility.

But here is the nuance: failure risk is governed by the size, shape, and location of the largest defect, not just the total amount of porosity.

- Shape matters: Irregular shrinkage pores are far more dangerous than round gas pores. Their sharp, jagged corners create high stress concentration factors.

- Location matters: A pore near the surface is much worse for fatigue life than one buried deep in the center.

Detecting the Invisible

You can’t manage what you don’t measure. Precision die casting requires rigorous detection beyond simple visual checks.

- X-ray Radiography: Great for a quick 2D look to spot internal issues.

- CT Scans (Computed Tomography): The gold standard. It gives you a full 3D analysis to measure the exact size and sphericity of defects.

- Integrated Simulation: We don’t just guess; we simulate. By coupling casting simulation (like MAGMASOFT) with mechanical performance simulations (FEA), we can predict how porosity will affect the final part. This lets engineers design robust parts that tolerate controlled levels of porosity, rather than applying massive, wasteful safety factors.

Engineering Strategies for Mitigation

Minimizing casting porosity requires a holistic strategy. It starts with the melt and ends with the machine parameters.

1. Melt Quality Assurance

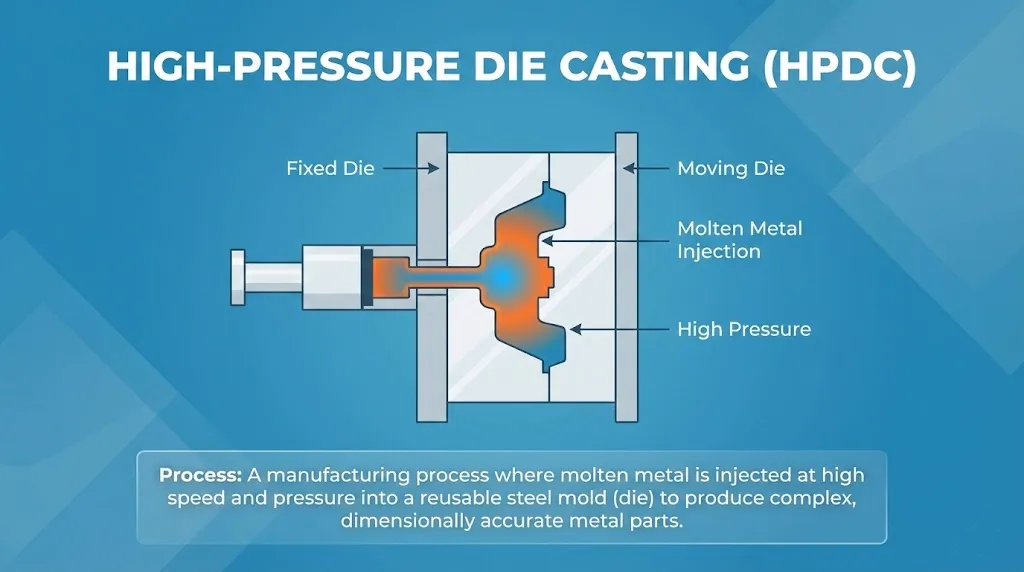

Hydrogen is a primary cause of gas porosity in aluminum. Rigorous melt treatment is non-negotiable. Techniques like ultrasonic-assisted rotary degassing are effective because they remove both dissolved hydrogen and detrimental oxide inclusions.

2. Optimize the Process

Precision lies in the details of your die casting tooling and parameters:

- Gating and Venting: Design runners to ensure laminar flow. You need adequate overflow wells to serve as "trash cans" for trapped air.

- Shot Profile: Precise control of the plunger speed prevents wave formation ("surfing") in the shot sleeve, which traps air.

- Biscuit Height: In HPDC, the metal dose size matters. A smaller biscuit increases the volume of air in the chamber relative to metal, exacerbating porosity.

3. Use Better Tech

For the most demanding applications, standard HPDC might not be enough.

- Vacuum-Assisted (VPDC): Pulls air out of the cavity before injection. Less air in the mold means less air in the part.

- Squeeze Casting: Maintains ultra-high pressure throughout solidification to mechanically "crush" micro-porosity.

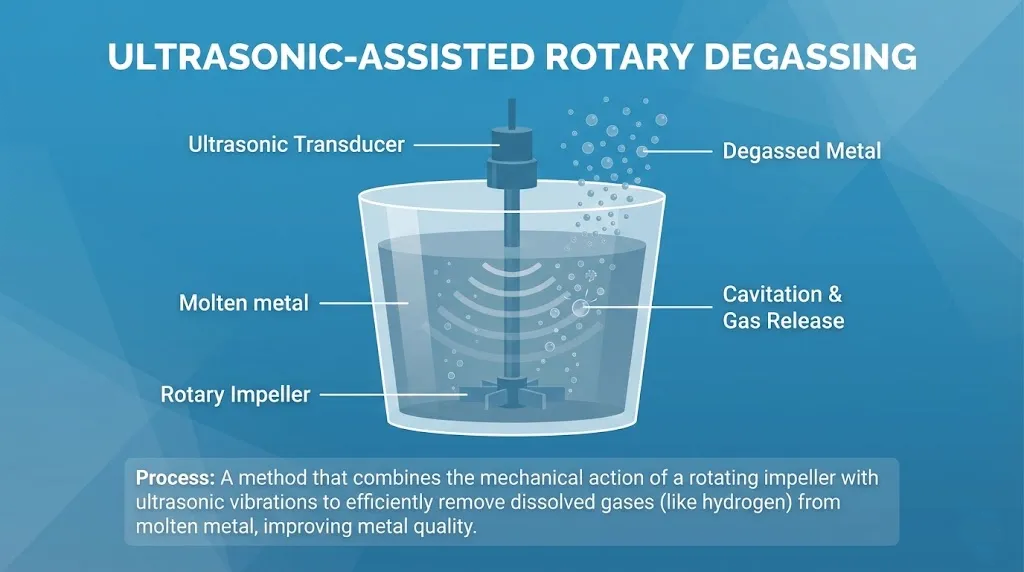

AI is Changing the Game

Manual inspection is slow and prone to error. New AI and Machine Learning models are now being trained on X-ray and CT data. These systems automate defect detection, making quality control faster and more accurate than ever before.

Conclusion

You can’t inspect quality into a part; you have to engineer it. Casting porosity is a challenge, but it is manageable. By understanding the root causes—whether gas or shrinkage—and employing advanced die casting tooling strategies, manufacturers can produce reliable, high-performance components.

Ready to De-risk Your Project?

Don’t let porosity compromise your component’s integrity. Contact Shanbo’s engineering team today for a free DFM review. We help you optimize your design before you cut steel.

Frequently Asked Questions

Q1: What is the main difference between gas and shrinkage porosity?

Gas porosity comes from trapped air or hydrogen and looks like smooth, round bubbles. Shrinkage porosity happens when metal contracts without enough feeding, creating jagged, angular voids.

Q2: Which type is worse for my part?

Shrinkage porosity is usually more dangerous. Its jagged shape acts like a sharp crack starter, which drastically reduces fatigue life compared to smoother gas pores.

Q3: Can you completely eliminate porosity in High-Pressure Die Casting?

Virtually impossible. The high speed of HPDC creates natural turbulence. The goal isn’t "zero defects" (which is expensive and rare); the goal is controlling porosity so it doesn’t affect function.

Q4: How does "biscuit height" affect quality?

The biscuit is the leftover metal in the sleeve. If it’s too small, it means there was too much empty air space in the sleeve before injection. That air ends up in your part.

Q5: Why use Vacuum-Assisted Die Casting (VPDC)?

It removes the air from the mold before the metal arrives. Less air means fewer gas pores, better ductility, and stronger parts.